Waterless

Dyeing Without Water

Zero Salt

Salt Savings 100%

Micro Emissions

Wastewater Discharge Approaching 0

01

03

Our Expectations

ECOHUES™ technology, provides consumers with more environmentally friendly color choices

Now

- Approximately 1 in 2 people globally do not have access to safe drinking water

- The textile dyeing industry is the second largest polluter of water globally

- 20% of the world's wastewater is generated by fabric dyeing and treatment

Future

-

Securing availability of drinking water by easing water crisis

-

Securing biodiversity by reduction of industrial polution

-

Ensuring a healthy and sustainable life by reduction of water pollution

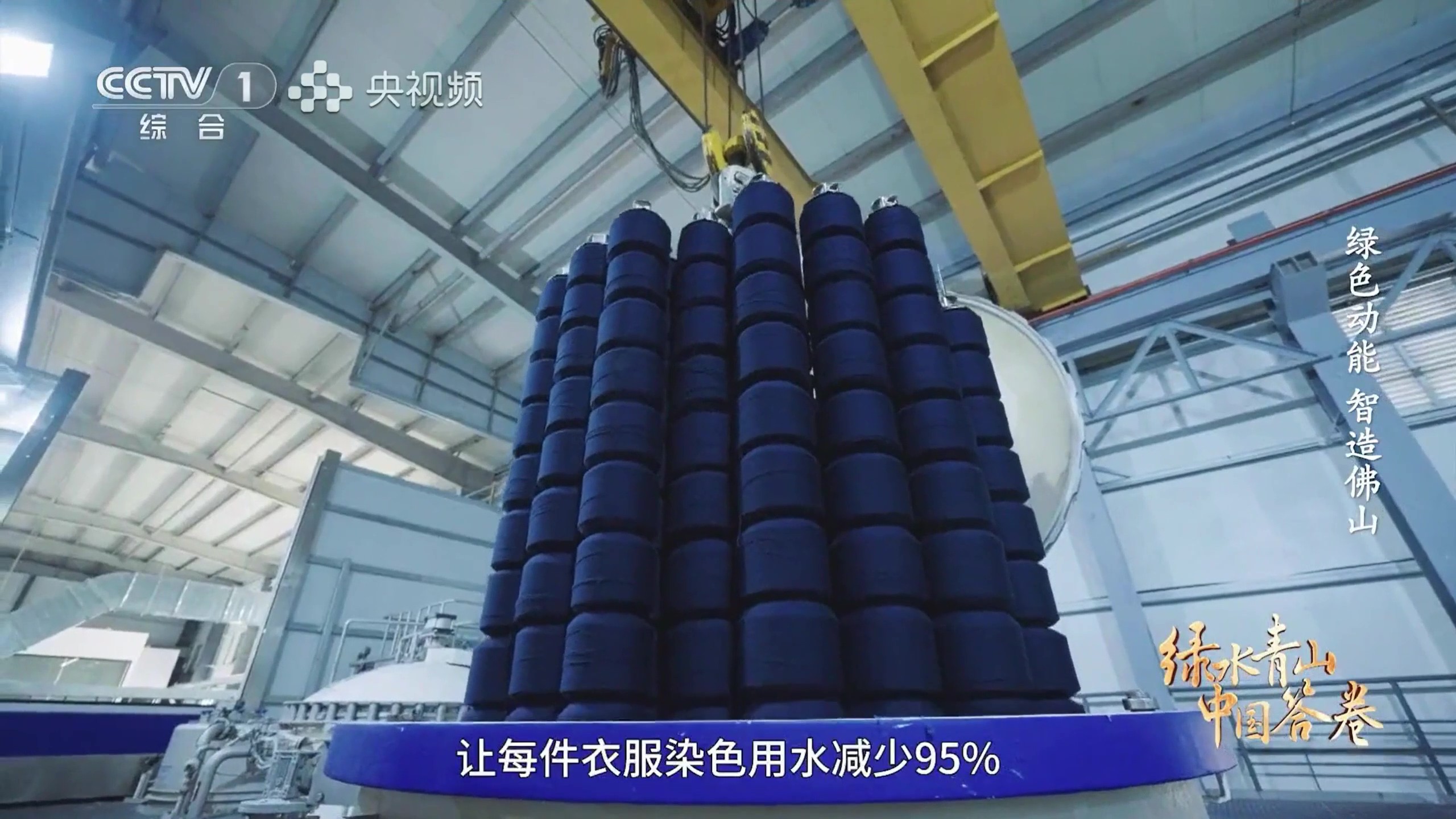

Since the birth of ECOHUES™ technology, we have saved 136969016.3 L of water for the Earth

Explore our technology

ECOHUES™ waterless dyeing is a new type of environmentally friendly dyeing technology that uses a recyclable non-aqueous medium instead of water for dyeing, significantly reduces the fashion industry's reliance on water.

Our brand service

When you see the ECOHUES™ brand hangtag on a product, it means that part or all of the them have been produced using ECOHUES™ technology and have been certified by ECOHUES™. You can purchase with confidence.

Our Partners

*Only includes some of our brand partners, and the list is in no particular order